Cheng Hong Automation

Design .Plan . Integration

- INTRODUCTION

- Poka yoke Error proof system

- POKA YOKE ERROR PROOFING SYSTEM SIMULATION AND APPLICATION

- CUSTOMIZED AUTO-ASSEMBLING MACHINE

- ASSEMBLING MACHINE UTILIZATION

- CUSTOMIZED AUTO-FINISHING PROCESS MACHINE

- FINISHING PROCESS UTILIZATION

- CUSTOMIZED MATERIAL FEEDER FILTER

- SPEC OF FEEDERS

- SUCCESS CASE

- OPERATIONS & SERVICES

- CONTACT US

- CHINESE

INTRODUCTION

To lead the market with techniques and quality, Cheng Hong’s best service brings you a better future.

About Cheng Hong

FOCUS MAKES PERFECTION

We’re specialized in electronic device integration and customized design for enterprises. With our experience in the business, Cheng Hong provides the most up-to-date technical supports and professional solutions. We work to go beyond your expectation, and we only give the best of us to valued customers.

Our Team

Integrity and Diligence

Automation and semi-auto assembly machine customized for your needs, including production line planning, capacity elevation, production planning and development. We help you overcome limitations on utilizing your space and visual system. Auto Parts Filtering and Vibrating Feeder are widely used in different businesses, we received positive feedbacks from our valued clients: San Shing Fastech Corp, SDI Corporation, Grand Gas Equipment Incorporation, MB Sturgis, and more. Cheng Hong always gives its best to you.

Our Vision

Bring Automation Into Your World

Facing the fast-changing international market, being innovative and groundbreaking is essential. Today, as cloud system and big data integration has become the trend of internet era, we help you upgrade production capacity and lower manpower costs. We bring you a great improvement by enhancing industrial performance with usage of internet. Work smarter, work better.

Integrity

We take our promises seriously and always give our best to meet your expectation.

Grit

Your satisfaction is our first priority. We push ourselves to complete every case with quality.

Innovation

Updating and upgrading is what we do. New technical supports are consistently developed in Cheng Hong.

Poka yoke error proof system

At the production site and storage equipment of assembled parts.Parts are generally based on the instruction sheet to select parts for inventory.But with the increase in the number of parts,the risk of errors due to similar shapes or similar parts is also increasing.Become an important issue to be solved in the production site.

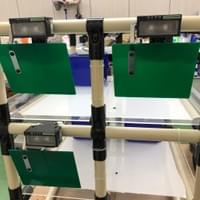

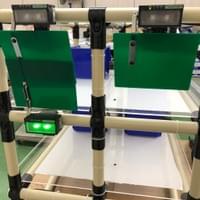

Import Poka yoke error proof system

It can be divided into input, take out two parts.As long as the scan order does not need to check the part name. Don't need to look east.There is light to indicate the location of the part Personnel can directly respond to request parts. Not only reduces the risk of component assembly errorsbut increase production, shorten working hours , and shorten the education time of new on-site personnel. It is also more flexible for the on-site personnel to transfer the division of labor Various information can be uploaded to MES (production management) Proactively collect and monitor production data generated during the manufacturing process.

To ensure the quality of production.

Customized Auto-Assembling Machine

We've got a top notch team!

Porous Studs

Auto-Assembling Machine

(with server)

Vehicle Lightbulb Auto-Assembling Machine

Auto-Welding Assembling Machine

Vehicle Electronic Window Pulley Riveting

Assembling Machine

Solar Power Wire Terminal Assembly Inspector

High Pressure Valve Assembling Machine

Hydraulic Riveting

Assembly

Machine

Auto-Drill Press Assembly Machine

Assembling Machine Utilization

Utilization Range

Cable TV Parts Vehicle Accessories

Office Hardware Medical Supplies

Footwear Household Items

Hardware in all businesses

Specialties

Auto-Assembly

Tolerance < 0.5mm

Quality Inspection 、Economizing Manpower

Fast-Accurate Inspection and Material Delivery

Customized Auto-Finishing Process Machine

We've got a top notch team!

Auto-Groove Finishing Processor

Auto-Drill Press Machine

Auto-Drill Remove Machine

Semi-Automatic

Metal Round Bar

Latch Machine

Four-axis machining system

Four-axis machining system

Brick production system

Six-axis simultaneous processing machine

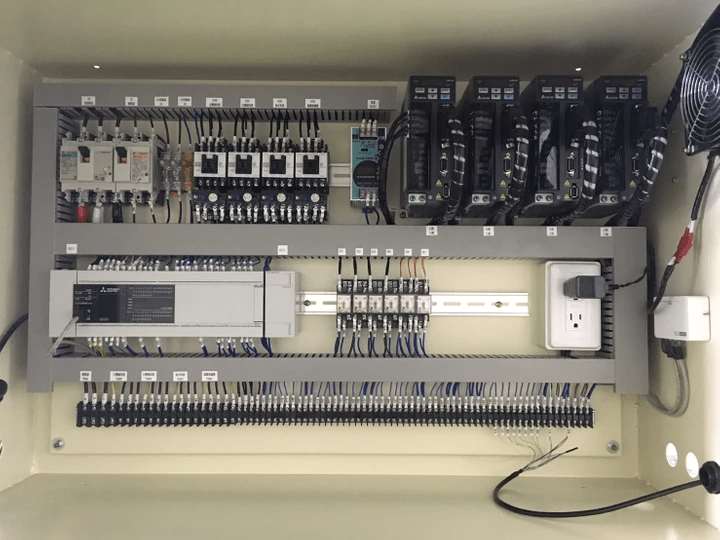

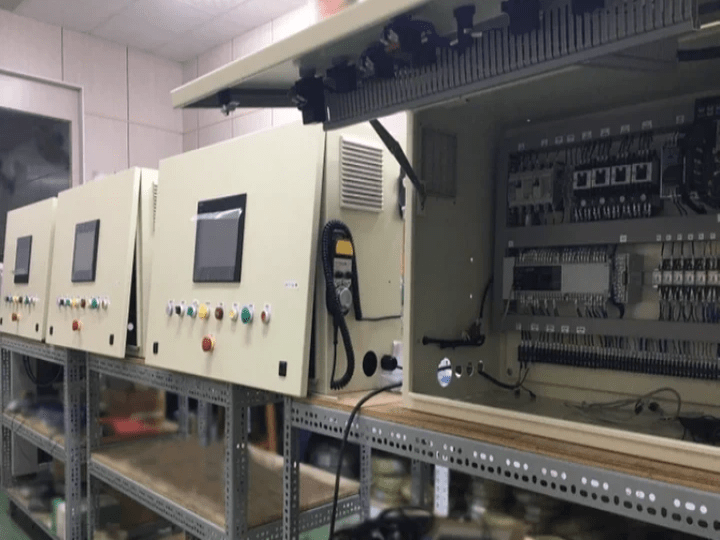

Integrated systemCNC&PLC& Man-machine interface

Six-axis simultaneous processing machine

Finishing Process Utilization

Utilization Range

Cable TV Parts Vehicle Parts

Electronic Parts Auto-Screw Driver

Auto-Drill Press Machine Auto-Welding Machine

Specialties

Separate Process(Tolerance less than 0.5mm)

Quality Inspection 、Economizing Manpower

Fast-Accurate Inspection and Material Delivery

Customized Material Feeder Filter

We've got a top notch team!

Multi-track Feeder

Auto-filter with Spring Bands

Spec of Feeders

Specialties

Zero Errors for Directions

Feeder Direction and Quantity DesignMulti-Track Direction Feeding

Accurate Fast Filtering and Feeding

Feeder Locating Sync with Robotic Clips

(Tolerance Smaller than 0.5mm)Auto-Inspection on Voltage and Electric Current

Less Labor Cost

Quality InspectionElectromagnetic Full Wave Vibrating Feeder

Input Voltage 110 / 220 / 380

Input Cycle of Wave (HZ)50 / 60

Vibration (count/min) 7000-8000 (Full Wave)

Moving Direction R (Clockwise) ; L (Anti-Clockwise)

Visual Diameter(mm) (R) 200 、250 、350 ; (L) 500 、700 、900

Object Weight (KG) (R) 8 、 24 、 40 ; (L) 83 、127 、220

Loading Weight (KG) (R) 3 、 6 、 12 ; (L) 20 、 30 、 40

Electromagnetic Half Wave Vibrating Feeder

Input Voltage 110 / 220 / 380 / 420 / 480

Input Cycle of Wave (HZ) 50 / 60

Vibration (count/min) 3000 - 3600

Moving Direction R (Clockwise) ; L (Anti-Clockwise)

Visual Diameter (mm)(R) 250 、350、450、600 ;(L) 900、1200、1500

Object Weight (KG)(R) 25 、40 、 70 、90 ; (L) 120 、170 、280

Loading Weight (KG)(R) 12 、 25、 40 、60 ; (L) 90 、150 、180

Electromagnetic Direct Vibrating Feeder

Type JL-1 、JL-2 、JL-3 / JL-20 、JL-30 、JB-40

Input Voltage 110 、 220、 380 / 110 、220、380、420

Input Cycle of Wave (HZ)50 、60 / 50 、60

Vibration (count/min) 7200 (Full Wave) / 3600

Tolerance Length (mm) 200、300、400 / 300*100、450*150、600*350

Tolerance Weight (KG) 1 、 2 、3 / 10 、 20 、 30

success case

- Assist in overcoming the limitations of space applications and visual system work environments

- Automatic parts screening component equipment (self-developed equipment)

- Vibrating directional feeder equipment (self-developed equipment)

End User

Actual performance introduction

- SDI Corporation

- GSK Group

- Mobiletron Electronics Co., Ltd.

- San Shing Fastech Corp

- HIWIN Technologies Corp

- Multiple Corporation

- Grand Gas Equipment Incorporatin

- Yung Shen Gas Appliances Co.Ltd

- Hou Ta Electric Cords & Plugs Co., Ltd

- CORNING International Taiwan

- Tong Lung Metal Industry Co., Ltd.

- Provide automated and semi-automated processing machines / assembly machines for customer needs

- Production line planning, capacity improvement, process design and development

End User

Actual performance introduction

- SDI Corporation-----Auto-Assembling Machine

- Edscha Holding GmbH-----Auto-Assembling Machine

- Shin Pao Electronics Co., Ltd.-----Auto-Assembling Machine

- Hou Ta Electric Cords & Plugs Co., Ltd----- Auto-Assembling Machine

- Grand Gas Equipment Incorporatin----- Auto-Assembling Machine

- Yung Shen Gas Appliances Co.Ltd-----Auto-Assembling Machine

- ILLIDA Gas Appliance Co., Ltd.-----Auto-Assembling Machine

- Multiple Corporation-----Auto-Assembling Machine

- Da Yin Wei Tong Co., Ltd.-----Auto-Assembling Machine

- JK LOCK Co., Ltd.-----Auto-Assembling Machine

- Tong Lung Metal Industry Co., Ltd.-----Auto-Assembling Machine

- MB Sturgis Inc-----Auto-Assembling Machine

- JANNYEI INDUSTRY Co., Ltd.-----Auto-Assembling Machine

- William Tools Co., Ltd.-----Auto-Assembling Machine

- Yan Lin industral Co., Ltd.-----Auto-Assembling Machine

- CHANG YUNG Metal Work Co., Ltd.-----Semi-Automatic processing Machine

- K&W Tools Co.,Ltd.----System Integration

- THA HO SHUN BRICK Co., Ltd.----System Integration

Address: No.23, Ln. 676, Sec. 1, Yuanshui Rd., Yuanlin City, Changhua County 510, Taiwan

Factory address: No. 92, Lane 131, Qitian Lane, Gongqi Village, Dacun Township, Changhua County

TEL:(04)836-7791 FAX:(04)839-1483

E-mail:cheng.hong617@msa.hinet.net

Please feel free to leave your contact info or visit us anytime!

Copyright © 2002 - 2017 Eckhart Consulting. All rights reserved.